High-performance materials from a pressure cooker

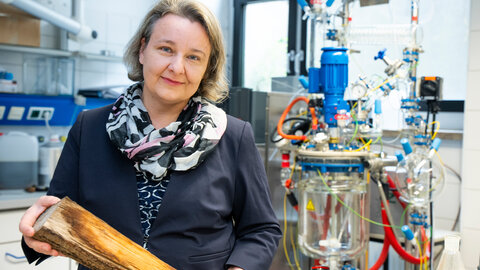

The manufacture of high-performance organic materials, such as those used in mobile phone displays or in filters for exhaust gases, often involve toxic substances. Miriam Unterlass has developed a process that is not only efficient but also environmentally friendly.

In a pressure cooker without gold or silver

Unterlass, a materials scientist and chemist at the Vienna University of Technology (TU Wien) took her lead from nature. Crystals form in water reservoirs deep inside the earth that are exposed to extreme heat and high pressure. This underground water, several hundred degrees hot, can be seen in places where it emerges at the surface as a geyser or hot spring. Unterlass uses “pressure cookers” to imitate this underground process, which is called hydrothermal crystallisation.

“In this way, we produce high-performance polymers that have a high crystallinity, or, in other words, a high degree of order at the molecular level,” explains the researcher.

What is new is that this process can also be used for organic compounds. “We work at high temperatures and high pressure,” explains the chemist. “This is abnormal in the synthesis of organic structures. One might think that the organic molecules would break down in such an extreme environment. But we use exactly this process to produce high-order crystalline structures from simple molecules. The starting materials are compounds consisting exclusively of carbon, nitrogen and oxygen. These substances are very light and easily available. This makes the newly developed materials lighter and avoids consuming any rare basic materials such as gold or silver,” notes Miriam Unterlass in explaining the advantages of these processes.

Fine-tuning for optimum conditions

The laboratory at TU Wien is equipped with pressure reactors of different sizes. For each system, the researcher needs to identify the best respective conditions. Some materials are produced at 220 degrees centigrade over several days, others at even higher temperatures, but in a very short lapse of time. Once the optimum conditions have been identified, the pressure reactors produce polymers that are resistant to chemicals and can withstand cosmic radiation and temperatures above 600 degrees centigrade.

Applications include battery packs or exhaust filters

The resulting materials are in great demand. The organic skeleton structures can be used, for instance, as molecular sieves in which ions of a certain size can be guided in the required direction for lithium-ion batteries in mobile phones or PCs. They can also be used to filter industrial exhaust gases.

The high-performance polymers produced by the research team at the Institute of Material Chemistry in Vienna are characterised by their special stability and temperature resistance. “Previously, this required toxic, expensive and environmentally harmful solvents. We can do it with just water,” enthuses Unterlass. This method is thus very environmentally friendly compared to conventional processes.

FWF funding as a game changer

In 2017, the innovative work of Miriam Unterlass was recognised by the generously endowed START Award, a grant from the Austrian Science Fund FWF to young scientists for outstanding achievements. According to Unterlass, this distinction was a game changer for her research career. “Receiving this seal of quality brought me a lot of recognition at my university and in the Austrian and international world of research, and to me it was confirmation that I’m on the right track,” Unterlass happily notes.

“Phönix” and “Partnership in Research”

In her work, the researcher combines basic research with applicability. The year 2017 also brought her the Austrian “Phönix” prize, awarded annually by Austria Wirtschaftsservice to start-ups, spin-offs and for the development of prototypes. In addition, Unterlass does research on applications of hydrothermally produced materials in composites for aviation and electronics through a “Partnership in Research” project funded by the FWF and the Christian Doppler Research Association. She is currently in the process of establishing a start-up. The researcher was helped greatly on her way to entrepreneurship by the research and transfer support provided by TU Wien.

“Startup Camp”

Once a year, TU Wien organizes an internal “incubator” workshop lasting several days to find out whether there are new technologies that would be interesting for start-ups. In the one-week “Startup Camp”, teams try to test technologies for their economic viability. “This gives rise to new questions: How much does your product cost? How much would other companies ask for it?”, says Unterlass. “The interesting thing here was: you can’t answer all these questions, but you do realise which new answers you have to find.”

A different world

In this encounter with a “different world”, the chemist also became aware that she needed a partner for the business side. “I’m a researcher, and I’m determined to work in academic research. I can only devote a limited amount of my time to an business enterprise. Our research is not an app that can be rustled up in no time by an employee.” With the support of the TU’s internal “incubator” she has found an ideal business partner, someone with wide commercial experience. “He’s great and has the necessary business know-how,” says the young female entrepreneur.

Choice of studies as an “act of providence”

The 32-year-old researcher has been working at TU Wien for six years. She says her choice of studies was the result of an “act of providence”. Having grown up near Nuremberg, Unterlass spent an exchange year at a school in Brittany and did her A levels there. Back in Germany she found out that the French school-leaving certificate permitted her to study in her home country only those subjects that she had chosen as her majors in France – and these were geology and biochemistry. Choosing between these two subjects she opted for chemistry, doing a double degree at the University of Würzburg and the École Supérieure de Chimie Physique Electronique in Lyon. This approach enabled her to complete half of her training in Germany and the other half in France. Ultimately, the researcher-to-be did her studies in chemistry, process engineering and materials science in Würzburg, Southampton and Lyon. In 2011, she obtained her doctorate at the Max Planck Institute for Colloids and Interfaces in Potsdam-Golm, Germany. She then did postdoctoral research at the École Supérieure de Physique et de Chimie Industrielles de la Ville de Paris (ESPCI) in Paris.

Bird’s eye view

The scientist describes her stays abroad as very formative. She felt the desire to be independent very early on. “I left home when I was fifteen. My various experiences abroad taught me to see the world multidimensionally. They also helped me to develop a bird’s eye view and thereby overcome one’s own narrow focus,” she explains.

Inexperienced, but a lot of zest

As a student she knew right from the start that she wanted to stay in research. It was in 2012, when she was doing her postdoc in Paris, that she was offered a tenure-track position at TU Wien, where she established her first research group at the Institute of Material Chemistry at the young age of 26. “When you are so young, you may not have brilliant people skills and you make mistakes, but you are also bold and have a lot of oomph,” is how she sums up the advantages and disadvantages of occupying a managerial position at such a young age. “I think it’s great and would recommend everyone to tackle things early in life,” is her advice to young colleagues.

“Work hard, but work happy”

Her aspiration is for her work to be “world class”. In her executive role, she considers it important to give co-workers a great deal of freedom in their research and she takes care to ensure that they have the opportunity to develop. There is also room for failures and mistakes as long as they are dealt with openly and honestly. “We’re supposed to be our own harshest critics, but you don’t get chewed out for the occasional blunder,” she says. Her motto: “Work hard, but work happy.”

Hybrid materials

In the coming years, Unterlass wants to go mainly in two directions: On the one hand, she would like to continue working on hybrid materials, i.e. developing processes that make it possible to combine organic and inorganic substances in their molecular structures in order to produce new materials that combine different properties of their input materials, such as flexibility and stability.

Smart new dyes

Her second line of activity concerns organic substances for biological applications. Since the end of 2018, Unterlass has held an associate position at the Center for Molecular Medicine (CeMM) in Vienna, where she is working on the development of new dyes for staining cells. “We not only want to produce new dyes that have properties such as fluorescence or high temperature stability, but we also want to design new, smart processes that are environmentally friendly,” she explains.

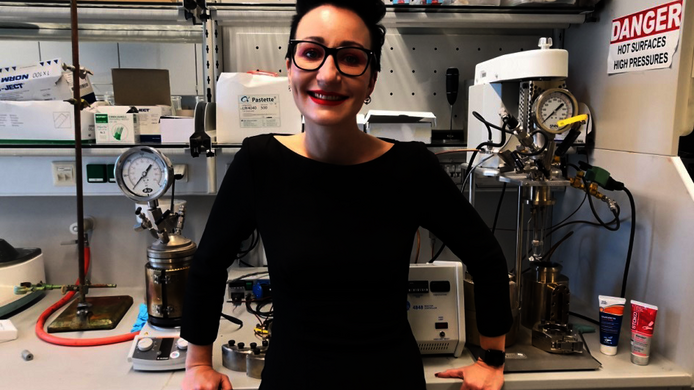

Vienna is “the most beautiful city”

The German-born researcher considers her chosen home of Vienna to be the “most beautiful city”. “Although I’ve been to a lot of great cities and universities, I like Vienna best,” she enthuses. The researcher, who likes to dress in dark colours and wear bold make-up — her red lips and red eyeshadow have become her trademarks — not only appreciates Vienna’s architecture and cultural offerings, but also the city’s research landscape: “The research here is international and there is a dense network of research institutes,” she notes. This also makes it easy to get into contact with one another: “I cooperate with many colleagues from the University of Vienna, the CeMM or the ÖAW,” she notes, underlining the benefits of the situation. She also feels that researchers are appreciated in Vienna.

Flatter hierarchies at universities

What Miriam Unterlass would wish to see at Austrian universities, however, are flatter hierarchies. “While scientists are expected to strive for independence, this can harm their career in the prevailing system,” she says, pointing out this contradiction. In that context, one should also consider whether the system of professorial qualification is still appropriate. “Sometimes, the good people are precisely those who want to be independent, and they are often prickly” observes Unterlass, and she counts herself as being one of them.

Personal details

In 2012, the chemist and materials scientist Miriam Unterlass received a position at TU Wien, where she heads the “Advanced Organic Materials” research group. Born in Germany, she studied chemistry, materials science and process engineering in Würzburg, Southampton and Lyon. In 2011, she received her PhD from the Max Planck Institute for Colloids and Interfaces in Potsdam-Golm, Germany. Then Miriam Unterlass did postdoctoral research at the ESPCI in Paris. In 2017, she was awarded the FWF’s START award for her project “Hydrothermal to functional organic scaffold structures”. In the same year, she was awarded the Phönix start-up award by Austria Wirtschaftsservice.