Konnichiwa, medical patches!

“We were particularly impressed by the importance attributed to work, since our Japanese colleagues do not consider work a necessary evil, but a source of fulfilment and a central element of their lives. What a remarkable attitude!” reports Andreas Petritz. “Some of the colleagues in the team could have retired a long time ago, but they carry on working anyway because they enjoy it,” says Petritz. What started as a small idea grew into a vital experience he would not want to miss. Between March 2018 and March 2020 he did research in Japan together with his wife Esther Karner-Petritz.

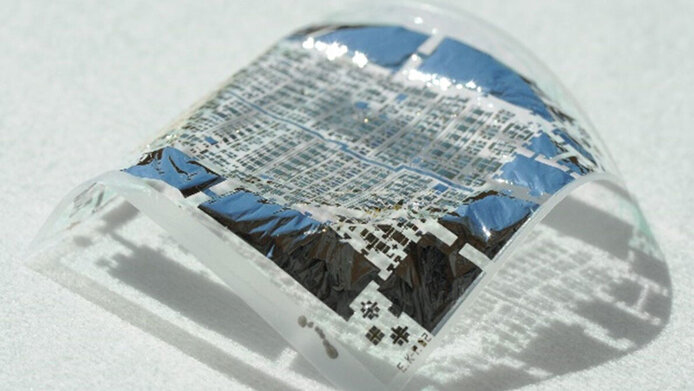

In the context of an Erwin Schrödinger Fellowship of the Austrian Science Fund FWF, he developed “OFES e-Skin” at the Sekitani Lab of Osaka University. It is a kind of electronic skin consisting of films equipped with sensors and electronics. The sensor films he uses are ultra-thin, three times thinner than cling film, as well as biocompatible, i.e. skin-compatible, and they react very sensitively to even the minutest changes in pressure. When such a patch is applied to the neck, it can record various vital parameters such as heart rate, blood pressure, pulse wave and arterial stiffness.

Energy harvesting

Apart from being used as a sensor, the patch can be used for another remarkable function: energy harvesting. When the sensor patch is applied to the elbow, for instance, and equipped with special electronics, it registers every movement, and the resulting biomechanical kinetic energy can either be stored or immediately converted. “The objective is to produce a completely energy-autonomous medical patch that can easily adhere to any object and can be used in a variety of ways. At some point sensors may even be able to support wound healing,” Petritz envisages excitedly. Although the development of an “electronic skin” has been strongly advanced in recent years, there is still a lot of work to be done before it is ready for a market launch. The range of potential areas of application includes robotics, artificial prostheses and biomedical instruments, but also “wearables” – serving as fitness trackers, for instance.

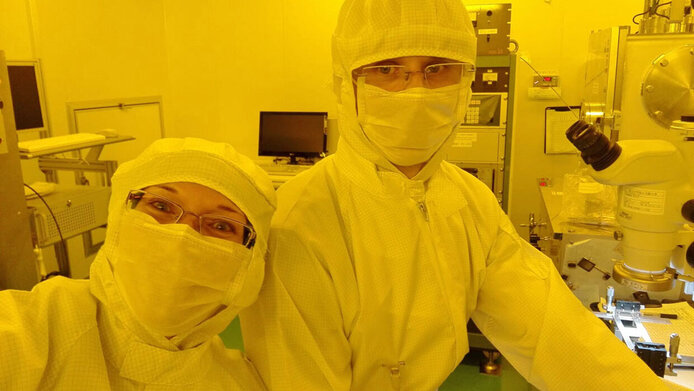

Hatsuhinode - the first sunrise of the year

Andreas Petritz describes the time spent with his wife in the Japanese port city of Osaka as exciting and instructive. “We still observe a typical Japanese custom called hatsuhinode: at daybreak on 1 January, you go to a place offering a good view to watch the first sunrise of the year. That is a very special experience,” Petritz recounts. At the university, he spent several hours wearing special clothing in the low-dust cleanroom, where the concentration of airborne particles is required to be kept low. Any dust particle would obstruct the application of thin polymer or metal layers that are needed for sensors and electronics. “You have to make sure you work cleanly. Every mistake, every lapse of concentration distorts the result,” he explains. Then comes the characterisation with different measuring devices, but the step he enjoys most is the final testing of a functioning component.

Smart wind turbines

Nowadays Andreas Petritz is to be found at his desk in Weiz, Styria. He is a senior postdoc at the Institute for Surface Technology and Photonics, which is part of the Joanneum Research institution. “The longer you are a staff member, the more office work you have,” says Petritz. In the context of the European H2020 project SYMPHONY (Smart Hybrid Multimodal Printed Harvesting of Energy), he is currently applying his knowledge to the development of an energy-autonomous sensor system. The system is designed to regularly check the status of a machine, for instance when it is attached to the rotor blades of a wind turbine. In this way, vibrations can be measured and any cracks or icing up can be detected at an early stage. This saves maintenance and repair costs and ensures a longer turbine life. The system can also reduce energy consumption when it comes to heating and cooling rooms using smart floors that track human presence and movement, or remote hose-pressure control for e-bikes. In addition, the technology can be integrated into stretchable and flexible components.

Andreas Petritz has not severed his bonds with Japan. He has made very good contacts there and would like to expand the cooperation further. Even while he is still working on a second publication, he is planning a new project in cooperation with the Sekitani Lab. Petritz will submit the funding application within the framework of the bilateral programme offered by the FWF and the Japan Society for the Promotion of Science (JSPS).

Personal details

Andreas Petritz studied experimental physics at Karl Franzens University in Graz and has been working as a research assistant at Joanneum Research-Materials at its Weiz site since 2011. In the context of an Erwin Schrödinger Fellowship of the Austrian Science Fund FWF, he worked on the development of an electronic skin. The “OFES e-Skin” project (2018-2020) was conducted in Tsuyoshi Sekitani's research group at Osaka University in Japan.

Publication

Andreas Petritz, Esther Karner-Petritz, Takafumi Uemura et al.: Imperceptible energy harvesting device and biomedical sensor based on ultraflexible ferroelectric transducers and organic diodes, in: Nature Communications 2021