Discover more

How wood offcuts are converted to medicine

Fossil fuels permeate virtually the entire spectrum of our consumer and economic life. From cars to toothbrushes, from fields to baby diapers, we are dependent on the countless processes and products of the petrochemical industry – processes that have been “optimized” over decades and are comparatively inexpensive for the manufacturers. The circular economy could offer one way of counteracting this dependency. Its successes have, however, been modest to date.

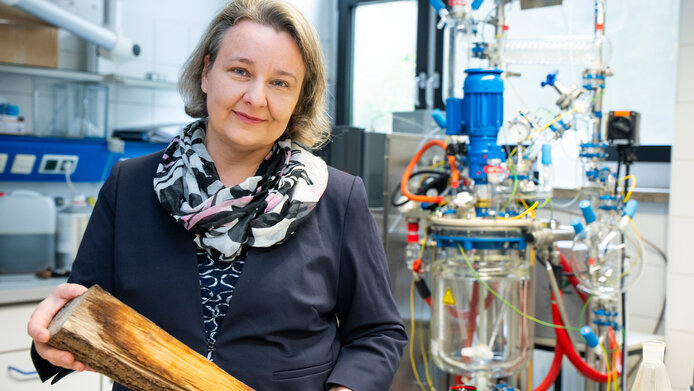

“Biorefineries, i.e. plants for the chemical processing of biomass, are still too expensive,” notes Katalin Barta. In order to become competitive and sustainable at the same time, we need completely new approaches. “We have to completely rethink every step in the cycle: from biomass extraction to production and recycling.” In Barta’s eyes, “completely rethinking” means starting at the molecular level.

Improving products with green chemistry

“I keep underlining that the circular economy will need a strong chemical component,” Barta says. Green chemistry is energy-efficient, based on sustainable raw materials, without toxic starting materials, wastes, or end products. “And every material we develop should ultimately also be energy-efficient, harmless healthwise and – in the case of polymers – easily recyclable.” And all this at a significantly lower cost. These ambitious goals can only be met if every single step in the process is taken into account from the word go. “Ergo, it's a holistic approach.”

Lignin is one biological material that has caught Barta's interest. Lignin is the structural element that provides stability for plants and trees. The processing of wood, for example in paper production, produces large quantities of lignin as a by-product. “If we want to work with lignin, Styria is the perfect place,” laughs Barta, who has been a professor of chemistry at the University of Graz since 2019 and heads the “sustainable catalysis” unit. In the context of the FWF-funded project “WoodValue: sustainable routes to bioactive heterocycles from wood,” she intends to use lignin to produce new bioactive molecules and drugs.

Zero Emissions Award

Researchers from all disciplines can submit climate-related projects for Austria's largest privately funded research award. The FWF's alpha+ Foundation provides EUR 900,000 annually to advance the energy transition through evidence-based knowledge from basic research.

A tough nut to crack

Lignin is a challenging material. “It protects wood from decay, hence it is particularly resistant,” explains Barta. It is particularly interesting for chemistry because lignin is the largest natural source of aromatics.

Aromatics – which have nothing to do with aroma – are ring-shaped, particularly stable molecules made of carbon atoms. They are the building blocks of organic chemistry and are found in countless products, from plastics, epoxy resins, dyes, and plasticizers to pesticides and pharmaceuticals.

Until now, aromatics have been obtained almost exclusively from petroleum. In order to turn them into more complex materials, the comparatively simple molecules must be reassembled – not unlike Lego bricks. However, each of the steps used to assemble the building blocks also requires energy and chemical aids such as solvents, reagents, and catalysts. In addition, each step produces waste, much of it undesirable.

Embracing complexity

“Our approach is based on the idea that if we start with a natural raw material such as lignin or aromatics derived from lignin, these already consist of several Lego bricks from the outset,” explains Barta. “Compared to petroleum, we then need far fewer steps to build complex molecules.”

For Barta, that means embracing complexity. “This approach allows us to arrive at a useful product in significantly fewer steps.” Her group has already been successful with this approach: “For example, we have succeeded in producing dopamine, a well-known pharmaceutical agent, from lignin.”

Barta's team is also constantly working on new methods of synthesis and catalysis. “We have developed a method for obtaining certain molecules that are very difficult to produce, such as benzoaxines, from wood chips or wood shavings in just three steps. To do it from petroleum, we would need 13 steps.”

Saving 10 synthesis steps not only improves the energy balance, but also the environmental factor or E-factor. This important measure in green chemistry indicates how many units of waste per unit of end product are generated during production, such as solvents, spent catalysts, or by-products of chemical processes. The smaller the E-factor, the more environmentally friendly and efficient the process and the product. In the pharmaceutical industry, it can be as high as 100: 100 kg of waste per kg of medicinal product. “This type of waste is very expensive. And more efficient processes are generally of great interest to this industry.”

About the project

The project “WoodValue: sustainable routes to bioactive heterocycles from wood” has set out to develop innovative and holistic chemical strategies for lignin, a by-product of the wood industry. The entire chemical process is based on the principles of green chemistry: using as few synthesis steps as possible, being non-toxic, energy- and resource-efficient. The environmentally friendly molecules produced from lignin serve as raw materials for high-value products such as pharmaceuticals.

Set to run until 2027, “WoodValue” was awarded EUR 345,000 in funding by the FWF.

On the way to green medicines

While Barta does not know whether industry has already taken note of the new method from Graz, the scientific community certainly loved it. This sustainable approach was also acknowledged by the privately funded Zero Emission Award for climate-relevant basic research, which Barta received in October from the FWF's alpha+ Foundation.

In the context of the WoodValue project, Barta hopes to obtain further molecules from lignin that can be used in pharmaceuticals. “We can either replicate what already exists, such as dopamine, or we can create entirely new molecules.”

This said, ‘entirely new’ also means that the compounds must first be tested: are they antibacterial? Are they effective against cancer? For this complex part of the development process, Barta is collaborating with the German Helmholtz Association, which has already identified positive properties in almost a third of the dozens of compounds found so far.

Spin-off for surfactants

In addition to medicines, the chemist is also interested in environmentally friendly polymers: materials made from sustainable raw materials that are just as robust as conventional plastics but can be recycled easily and effectively. She is supported in this effort by a generously endowed ERC Consolidator Grant.

Barta has already gone one step further with environmentally friendly surfactants for use in products such as shampoos, detergents and cosmetics. In 2021, she received an EIC Transition Grant for the PureSurf project, which focuses on spin-off activities. Cooperation partners are still being sought for the start-up company.

“It would be really fantastic and motivating for the whole team to launch our own bio-based products,” says Barta. She specifies that this requires scientific breakthroughs, because only truly innovative, intelligent, and affordable new products will be competitive.

About the researcher

Katalin Barta is a university professor of chemistry at the University of Graz. She previously conducted research at the University of California, Yale, and the University of Groningen. Barta is interested, inter alia, in chemical transformation methods for the wood component lignin.

Barta’s innovative research has already been recognized by numerous awards, including three ERC grants from the European Research Council, the EIC Transition Grant for founding the spin-off PureSurf, the Austrian start-up award “Phönix” (2023), and the Zero Emissions Award (2025) from the alpha+ Foundation of the FWF.

Publications

Modular synthetic routes to biologically active indoles from lignin, 2025